| WRS 12 AND WRS 12+ WATER

RECYCLE SYSTEM

The WRS 12 and WRS 12+ Water Recycle Systems are designed to

solve washwater disposal problems for the smaller user. These COMPLETELY

AUTOMATIC TREATMENT SYSTEMS will collect dirty, oily washwater and

process it so that it can be reused in your washing operation. The

recycle feed pump transfers the dirty water from a collection sump to

the treatment unit. Reagents are added to the water to kill bacteria and

odors, neutralize the pH, and remove pollutants such as oil, grease,

dirt, and sludge. These reagents, which are commonly used in drinking

water treatment, actually make the water much more ENVIRONMENTALLY

FRIENDLY and less hazardous for personnel doing the washing. The

treated water is then stored in the integral holding tank until needed

for washing.

The WRS 12 and WRS 12+ Water Recycle Systems are designed to

solve washwater disposal problems for the smaller user. These COMPLETELY

AUTOMATIC TREATMENT SYSTEMS will collect dirty, oily washwater and

process it so that it can be reused in your washing operation. The

recycle feed pump transfers the dirty water from a collection sump to

the treatment unit. Reagents are added to the water to kill bacteria and

odors, neutralize the pH, and remove pollutants such as oil, grease,

dirt, and sludge. These reagents, which are commonly used in drinking

water treatment, actually make the water much more ENVIRONMENTALLY

FRIENDLY and less hazardous for personnel doing the washing. The

treated water is then stored in the integral holding tank until needed

for washing.

The WRS 12 and WRS 12+ both treat 2 gpm (3000

gpd), which is enough for many washing operations. They are equipped

with many convenience features, including automatic priming and

degassing valves for the reagent pumps (manual priming valve on

coagulant pump), power cord with GFCI and15 amp 115 volt plug, and

integral water storage tank. The WRS 12+ is also provided with a

fiberglass reagents pumps enclosure, larger inlet strainer with

valve-in-head, flow meter, and filters status pressure gage. Both

systems come completely assembled and wired, ready to be set in place

and plugged into a 15 amp, 115 volt outlet. The water discharge

from the integral storage tank is pressurized to feed your pressure

washers, even if they are remotely located. Premium components and

quality construction insure the most troublefree operation possible.

WRS 12 AND WRS 12+ WATER RECYCLE SYSTEM

SPECIFICATIONS

| Rated flow rate: |

2 gpm (3000 gpd) |

| Electrical requirement: |

115 VAC, 60 Hz, 1 phase, 15 amp total |

| Recycle feed pump: |

Self priming centrifugal cast iron pump with 1/3

HP thermally protected motor. Mounted on the machine base on WRS

12+. Controlled by float switch in collection pit. Suction line

strainer and foot valve are provided. |

| Discharge pump: |

High head centrifugal pump with 1/2 HP thermally

protected motor. Provides pressurized water flow to pressure

washer and other uses. |

| Electrical controls: |

GFCI provided, prewired with 15 amp plug, 10 ft

cord Lighted switches for power, feed pump, coagulant pump,

oxidizer pump, pH adjuster pump, makeup water, and manual drain.

pH controller with digital display. NEMA 4 rated enclosure |

| Reagent metering pumps: |

Electronic controlled diaphragm pumps with stroke

rate and stroke length controls. Automatic degassing head on

oxidizer and pH adjust pump. Manual bleed valve on coagulant

pump. Pumps are mounted in a fiberglass enclosure on WRS 12+. |

| Inlet strainer: |

Large size in corrosion resistant plastic

housing. Valve-in-head housing on WRS 12+. |

| Filter system: |

20" long 20 micron filter cartridge for

final polishing. Two cartridges included with machine. |

| Sludge collection system: |

Large, disposable fabric filter sock collects

sludge. Two filter socks included with machine. |

| Make up water: |

100 psi maximum pressure. Automatically added as

required by application. |

| Recycle tank capacities: |

Coagulant tank- 50 gallons

Separator tank- 50 gallons

Storage tank- 50 gallons

Total water capacity- 150 gallons

|

| Recycle construction: |

Heavy duty polypropylene tank with unitized

construction. Schedule 80 PVC pipe used throughout. Heavy steel

base assembly. |

| Connection sizes: |

Machine inlet- 1 NPT

Treated water outlet- 3/4 NPT

Drain line- 1 NPT

Make up water- 1/2 NPT

|

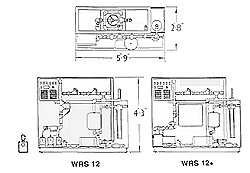

| Overall dimensions: |

5 ft 9 in long, 2 ft 8 in deep, 4 ft 3 in tall |

| Shipping weight: |

400 pounds |

| Options: |

Second pH adjusting pump. Additional treated

water storage capacity. Activated carbon water polishing

systems. Sand filter final polishing system. Pretreatment

systems, oil skimmers, and oily water separators. Ozone

treatment. Graduated reagent containers. Custom modifications

available. 798 |

|

|

|

| |

| Phone: 617-965-0007 |

Fax: 617-965-0097 |

| Toll Free: 1-800-770-BOOM |

Email: sales@boomenviro.com |

| |

|

| Factory Location: |

| 1 Coffin Avenue |

| New Bedford, MA 02746 |

| |

| BOOM Environmental Products® is

a registered trademark of Geotechnical Supply, Inc. |

|

|

|

|

|

|