Non-Woven Geotextiles for Oilfield Construction

Well Pads, Pits, & Roads

For use in Frac Pads and Ponds as part of containment systems with and without liners. Used all over the Marcellus Shale and other O&G drilling sites.

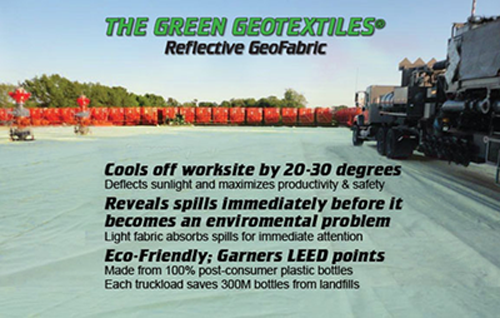

Available as The Green Geotextiles® made from 100% post-consumer polyester extruded from recycled bottles and as The Grey Geotextiles™ made from post-industrial polyester. Both garner LEED points. Can also be recycled again after use saving even more landfill space.

THE GREEN GEOTEXTILES® NON-WOVEN SPECIFICATIONS

Style: NONWOVEN

100% POST CONSUMER

POLYESTER |

Test Method |

GN100 |

GN160 |

GN200 |

GN250 |

GN300 |

| Widths (ft) |

12.5 |

15 |

15 |

15 |

15 |

15 |

| Length (ft) |

400 |

400 |

300 |

300 |

300 |

| Thickness (mils) |

ASTM D-1777 |

60 |

70 |

120 |

130 |

145 |

| Weight (oz/yd2, min.) |

ASTM D-3776 |

4.5-5 |

6 |

8 |

10 |

12 |

| Grab Strength (lbs) |

ASTM D-4632 |

100 |

160 |

200 |

250 |

300 |

| Elongation (%) |

ASTM D-4632 |

50 |

50 |

50 |

50 |

50 |

| Trapezoid Tear (lb) |

ASTM D-4533 |

45 |

60 |

85 |

100 |

115 |

| Mullen Burst (psi) |

ASTM D-3786 |

210 |

300 |

350 |

460 |

580 |

| Puncture Strength (lb) |

ASTM D-4833 |

65 |

95 |

110 |

150 |

175 |

| AOS (U.S. Sieve Size) |

ASTM D-4751 |

70 |

80 |

80 |

70-140 |

100 |

| Permittivity (sec-1) |

ASTM D-4491 |

2 |

1.7 |

1.5 |

0.94 |

1 |

| Water Flow Rate (gpm/ft2) |

ASTM D-4491 |

140 |

110 |

110 |

75 |

75 |

| UV Resistance (%) |

ASTM D-4355 |

70 |

70 |

70 |

70 |

70 |

| Water Retention (gal/ft2) |

ASTM F726-06 |

0.05 |

0.06 |

0.08 |

0.10 |

0.12 |

THE GREY GEOTEXTILES™ NON-WOVEN SPECIFICATIONS

| Style |

Test Method |

AEF 480HS |

AEF 680HS |

AEF 880 |

AEF 1080 |

AEF 1280 |

AEF 1680 |

| Widths (ft) |

12.5 |

15.0 |

12.5 |

15.0 |

12.5 |

15.0 |

12.5 |

15.0 |

12.5 |

15.0 |

12.5 |

| Length (yd) |

400 |

400 |

400 |

300 |

200 |

200 |

| Fabric (oz/syd) |

4.0 |

6 |

8 |

10 |

12 |

16 |

| Composition |

Post-industrial polyester |

Post-industrial polyester |

Post-industrial polyester |

Post-industrial polyester |

Post-industrial polyester |

Post-industrial polyester |

| Thickness (mils) |

ASTM D-1777 |

60 |

70 |

120 |

130 |

145 |

175 |

| Grab Strength (lbs.) |

ASTM D-4632 |

105 |

160 |

205 |

250 |

300 |

380 |

| Elongation (%) |

ASTM D-4632 |

50 |

50 |

50 |

50 |

50 |

50 |

| Trapezoid Tear (lb) |

ASTM D-4533 |

45 |

60 |

85 |

100 |

115 |

150 |

| Mullen Burst (psi) |

ASTM D-3786 |

210 |

250 |

350 |

460 |

580 |

750 |

| Puncture Strength (lb) |

ASTM D-4833 |

65 |

95 |

110 |

150 |

175 |

240 |

| A.O.S. (U.S. Sieve) |

ASTM D-4751 |

70 |

80 |

80 |

70-140 |

100 |

100 |

| Permittivity (sec-1) |

ASTM D-4491 |

2 |

1.63 |

1.5 |

0.94 |

1 |

0.7 |

| Water Flow Rate (gpm/ft2) |

ASTM D-4491 |

140 |

110 |

110 |

75 |

75 |

50 |

| UV Resistance (%) |

ASTM D-4355 |

70 |

70 |

70 |

70 |

70 |

70 |

Courtesy of Countrywide, Marcellus, PA

Courtesy of Barber-Webb

Made In USA

1-800-770-2666

|